Capital Raising

CLOSED

Oscar Resources Limited

Iron Ore company utilising breakthrough technology

INDUSTRY

Resources

Investment Highlights

Company Overview

Transaction Overview

Additional Information

Team

Transaction Summary

Oscar Resources Limited

This offer closed August 2022. If you would like to discuss anything in relation to this company please contact us for further information.

All information on this page was current as at the date of closure.

Investment Highlights

Prime Location in the Hub of the Pilbara

Utilising new technologies to improve mineral recovery

Pre-IPO Opportunity

Company Overview

Gut health plays a key role in human health

Gut health plays a key role in human health

Oscar Resources is a Sydney-based mineral exploration and mining development company that centers on base and precious metals in the Pilbara, West Australia.

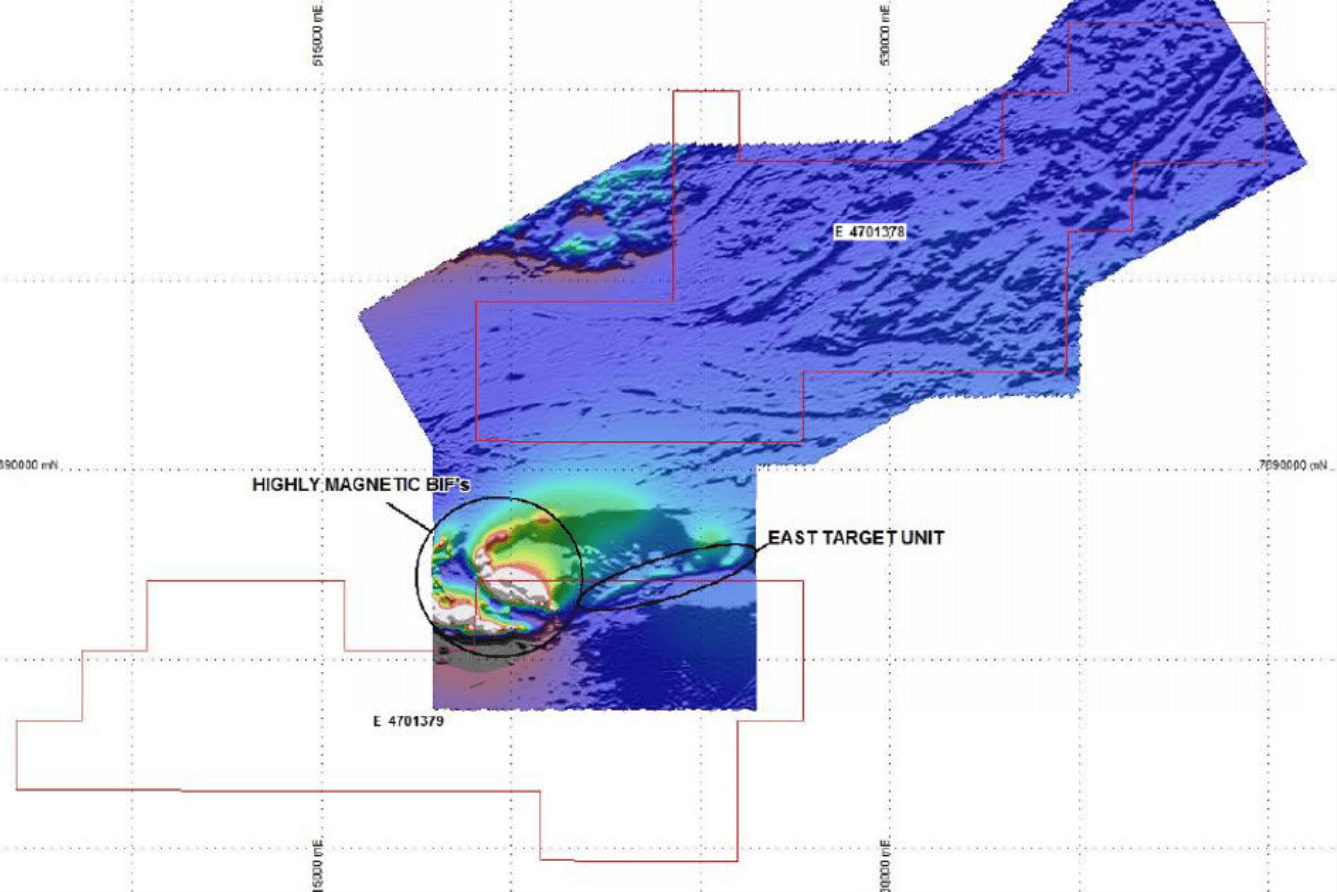

The Company’s current projects are the Mt Oscar Iron Ore Project and the Mt Oscar Gold Project and hold iron ore assets at Mt Oscar Main covering a total area of ~163Km2.

These tenements have and/or are close to necessary infrastructure which makes the project more competitive compared with others in the region.

Cutting Edge Technology

Oscar Resources uses cutting-edge technologies for ore processing, by working with technology and equipment providers.

They have developed equipment aimed at reducing mine operating costs and increasing product Fe grades and mass recovery, benefiting their shareholders.

Elutriated Magnetic Separation (EMS)

EMS technology is suitable for dealing with finely disseminated gangue (silicate) magnetite ores and capturing liberated fine magnetite particles, by grinding ores to P60 75µm and/or finer.

The EMS equipment size in operation has increased from 600 mm more than ten years ago to 2,200 mm nowadays and has been applied in many magnetite mines to upgrade concentrate grades to 65-67%Fe or replace flotation processes.

EMS technology has seen successful application in the nearby CITIC’s Sino Iron Project, upgrading 62.5%Fe to +67%Fe, which is likely to be applicable to the Mt Oscar Project.

Ore Sorting Technology

Ore Sorting technology introduces a new process of waste disposal and pre-concentrating iron ore with three stages of crushing and two stages of waste disposal, to recover both magnetite and haematite.

This is the first time that such waste disposal and the pre-concentrating process have been proposed in the industry.

It has great economic value and makes it possible for the development of hematite which was previously thought to be disposable. This process is also suitable for other minerals.

Want to learn more?

Fill in the expression of interest form below